In modern manufacturing, even small misalignments between supply, demand, and workforce can lead to serious consequences — delays, waste, underused capacity. This affects nearly every production-driven industry: automotive, electronics, pharmaceuticals, food and beverage, industrial machinery.

Despite automation, many operations still run on outdated schedules and disconnected systems — unable to adapt fast enough to real-world changes.

Why AI Makes a Difference

Even with automation, many factories still run on disconnected systems and outdated plans. Production doesn’t always match demand. Quality issues go unnoticed. Staffing often doesn’t reflect what’s really happening on the floor.

The result? Delays, waste, and lost opportunities.

Where AI Can Help Right Away

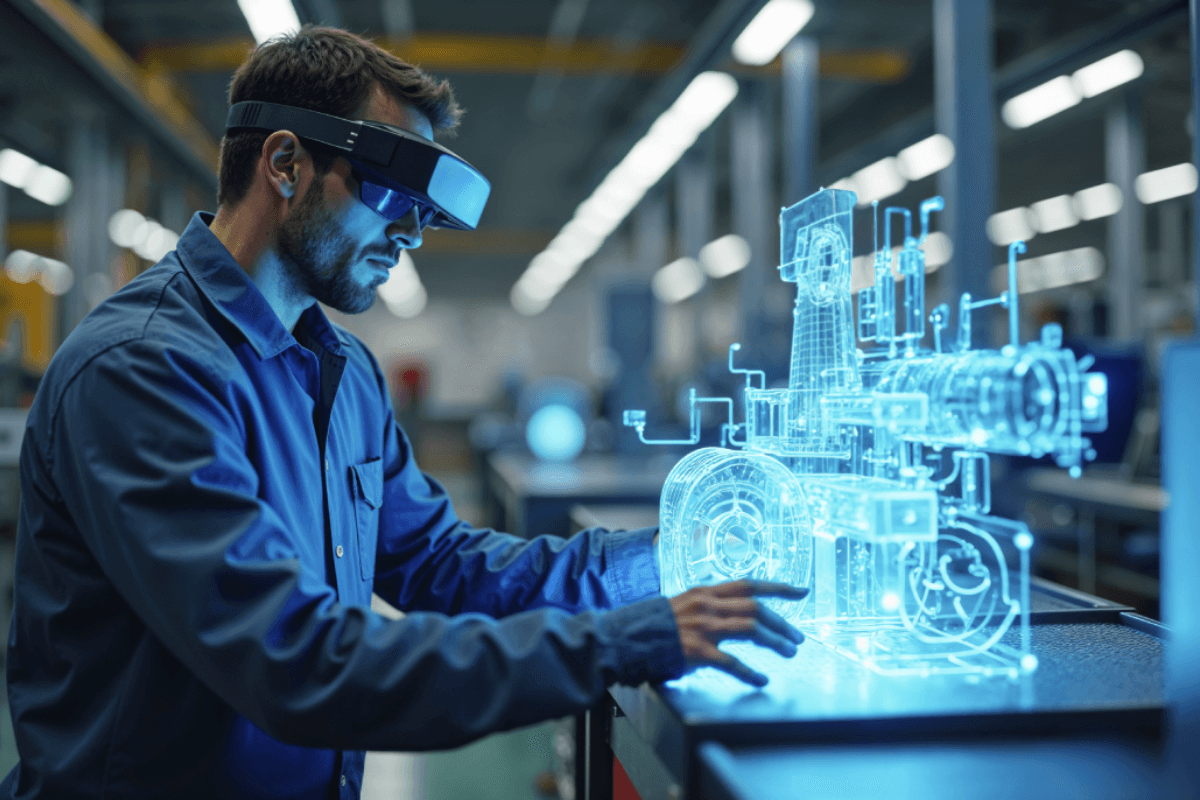

AI doesn’t replace people — it helps them work smarter. Here’s what it can do:

- Catch Problems Early

AI spots unusual patterns in machines or output before they cause bigger issues.

- Understand Processes Better

It finds hidden slowdowns or inefficiencies by constantly analyzing your data.

- Plan More Accurately

AI connects live data to planning — so you can align schedules, staff, and stock with real demand.

What the Data Says

- Up to 40% less unplanned downtime with predictive anomaly detection

- 10–15% efficiency gains within 90 days through AI-driven process analysis

- 15–20% increase in throughput by aligning staffing with machine performance

- AI uncovers hidden bottlenecks that humans often miss — using pattern recognition, not assumptions

(Based on findings from industry studies and case reports by LLumin and LeadsInfra)

How to Get Started

No need to replace your entire MES or ERP. Start small — use your existing data to detect anomalies or analyze a key process.

Siesta AI’s modular tools plug into your workflows and deliver results fast — with your team still in control.